Just as NASA has a Mission Control room to monitor spacecraft, Fort Lauderdale-Hollywood International (FLL) has a ramp control room to track aircraft in non-movement areas. Earlier this year, the airport installed a high-tech system that is especially valuable for monitoring and managing aircraft in areas outside of the visual field of air traffic controllers.

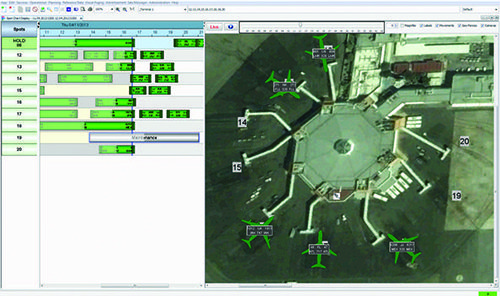

The windowless room features two six-panel video walls that provide ramp controllers with a panoramic window-like view of the entire airfield. The system also includes an interactive, real-time map display that allows them to click on any gate for a thermal high definition pan/tilt/zoom view and improve on-block and off-block status updates.

“Our airport is land poor, and to create new multimillion-dollar towers for line of sight didn’t make sense,” explains Michael Nonnemacher, FLL’s acting assistant director of Aviation. “The Virtual Ramp Control program is a technological response rather than a traditional brick-and-mortar solution. Our ramp controllers can see the whole airfield from one room, which operates like an FAA Air Route center.”

|

facts&figures

Project: Virtual Ramp Control |

Managing Expansion

The new tech-centric ground control system is the latest initiative in a series of improvements FLL has executed to help manage increasing traffic levels. What began as an abandoned nine-hole golf course in 1929 has evolved into one of the fastest-growing airports in the United States. Currently, FLL is on pace to enplane 30 million or more passengers by year-end.

Throughout the decades, the South Florida airport has outgrown its facilities time and again. Several years ago, FLL drafted a $2.3 billion improvements and renovations program to modernize its terminals, add gates and build a second runway. The runway opened in 2014 to great fanfare, expanding the airport’s maximum capacity to 425,000 flights per year-an effective increase of 40%. As a result, Emirates announced it would begin daily 777 service from Dubai to Fort Lauderdale in 2016-a coup for the market and airport.

Amid the continual growth, FLL officials found they needed to take a hard look at the airport’s blind spots-literally, not figuratively. From the bird’s-eye view of the FAA air traffic control tower, there were a handful of non-movement areas that were not visible to controllers. To maintain safe operations, they relied on ground personnel to report the status of incoming and outgoing aircraft from particular gates.

Given its high traffic and limited airside infrastructure, FLL typically has aircraft docked at every gate overnight, plus another 15 or so parked in two remote zones. Each morning, Robinson Aviation, the company that provides ramp control services at FLL, sent a ramp employee to the gates that were out of controllers’ line of sight to log which aircraft were on block.

Given its high traffic and limited airside infrastructure, FLL typically has aircraft docked at every gate overnight, plus another 15 or so parked in two remote zones. Each morning, Robinson Aviation, the company that provides ramp control services at FLL, sent a ramp employee to the gates that were out of controllers’ line of sight to log which aircraft were on block.

Don Starbuck, a former FAA air traffic controller and supervisor, manages FLL’s virtual ramp control facility for Robinson Aviation. “We had access to line of sight, but we could not see all the gates,” he says of the previous system. “We had to keep track of them via a dry erase board to know if they were empty or filled.”

Now, the Virtual Ramp Control System from Amadeus (formerly AirIT) provides the critical information in video format. Company personnel estimate that before the new system was installed, controllers could view 65% to 70% percent of the airfield at any given time. The virtual system is designed to provide full visibility.

“Effectively what we’re doing is displaying the information graphically,” explains Jeff Shull, the company’s vice president of implementation and delivery. “We use disparate systems and combine them to create a graphic interface. Basically, in the morning when the airport starts operations, we have a complete database of what is scheduled for that day.”

The company’s Virtual Airfield Management System (VAMS) simulates an “out-the-window view” of geographically dispersed aprons, remote stands and aircraft parking areas by consolidating multiple images into one operator display. The aerial view of the airport includes accurately scaled images of terminal buildings, gates, stands, remote parking positions, cargo facilities and maintenance areas. With this system in place, the airport can deploy resources to other areas.

The company’s Virtual Airfield Management System (VAMS) simulates an “out-the-window view” of geographically dispersed aprons, remote stands and aircraft parking areas by consolidating multiple images into one operator display. The aerial view of the airport includes accurately scaled images of terminal buildings, gates, stands, remote parking positions, cargo facilities and maintenance areas. With this system in place, the airport can deploy resources to other areas.

Shull describes the crucial tracking and handoff components as follows: “The ASDE-X (Airport Surface Detection Equipment, Model X) picks up the aircraft as it nears the runway. When a plane lands, we take the data tag from the aircraft and we follow the aircraft into the non-movement area. Then, it’s taken over by Searidge technology, which follows it to the non-movement area.”

Base Software

Amadeus recruited Searidge Technologies to the project team in 2012 to provide the video platform that depicts airfield traffic. Its high-grade remote video management system is a key component that allows the overall system to monitor aircraft from the time they land until they pull into their assigned gates.

By replicating a tower-like window view for an off-site location, the system enhances situational awareness on the airfield, explains Searidge Vice President Derek Bayford.

As for the transition from window to screen, Bayford reports that ramp controllers who have used the system say it doesn’t take long to get used to. It feels just like watching traffic from the tower, he explains.

“The virtual system allows ramp controllers to make intelligent decisions in real time,” he comments. “Through augmented reality thermal views and PTZ [pan/tilt/zoom] controls, ramp controllers can now see into areas that were previously not visible. If they can’t see it, they have to rely on ‘ground in, ground out.’ We give them eyes to anywhere in the area.”

The system is also scalable, so airports can choose to surveil as much or little of their airfields as desired. One airport might only need coverage on a specific side of the terminal or remote taxiway, while another needs “eyes” on its cargo area.

“The more information the airport has, the better able it is to make decisions,” says Bayford. “This can lead to more accurate flight information displays, too.”

Searidge provides a mix of different kinds of sensors to provide FLL visual access to every gate. This allows personnel to see any gate at any time, and make decisions according to what they see, explains Bayford.

The virtual system can expand for other uses, such as identifying foreign object debris and wildlife hazards, or interfacing with billing companies, he adds. Airports that regularly experience heavy fog could also benefit from the base tracking and monitoring capabilities.

FLL is currently not using the system for extra services, notes Bayford.

Integration Opportunities

Before it implemented the Virtual Ramp Control System at FLL, Amadeus had provided the Airport Operational Data Base (AODB) there for more than a decade. By tying the two together, the airport is able to funnel real-time information about flight operations from the virtual system to Flight Information Display System (FIDS) displays throughout the airport.

“Using all of the data available, the airport can be more efficient by analyzing the trends,” says Shull. “In Fort Lauderdale, this integration is going to give them an advantage. It makes them the most technologically integrated airport in the country.”

Shull says if airports are capturing robust data, they can create metrics and audit the information to develop new routes based on customer need.

“This kind of collaborative decision-making benefits all parties,” adds Nonnemacher.

On the Cutting Edge

The technology driving FLL’s new ramp control system is so emergent, some of the hardware that engineers specified became outdated before the procurement process was complete. “What we learned is that when you choose a high-tech solution like this, you need to be prepared to make it adaptable and portable to what you have,” Nonnemacher reflects.

When the project took longer than expected, camera technology improved in the interim, and the airport was able to install about half as many cameras as originally planned, notes Shull.

Durability was also a key issue. Despite four to six hours of damaging winds during Hurricane Irma, all but one camera was still working when the storm subsided, reports Starbuck. Because the system has other cameras pointed at the same gate, coverage was still intact.

“Even if a camera fails, we have backups,” he relates. “In fact, a number of cameras could fail, and we could still zoom in with others.”

The airport also keeps an inventory of spare cameras on hand, and a contractor can install a replacement in a matter of hours, he adds.

Tech & Towers

After operating with the virtual control system in place for almost a year, Nonnemacher describes the project as collaborative and forward-thinking. “We have to be a vanguard, because we don’t have another choice,” he muses. “Like many other airports, we’re capacity-constrained. We had two towers and still had blind spots. This system takes away the blind spots and gives our controllers good views of the whole field.”

Built-in safeguards and redundancies provide further confidence. The control center is designed to withstand a Category 5 hurricane and is equipped with a fire station and full-size generator that can operate its critical systems even if the airport loses power.

“I can’t really quantify the results, but prior to adding virtual ramp control, we had some wingtip collisions, and we had aircraft going head to head,” relates Nonnemacher. “Since we put this system in place, we haven’t had any of that.”