Atlanta Int’l Replaces Exterior Facade & Adds Lighted Canopies

Hartsfield-Jackson Atlanta International Airport (ATL) is in the midst of a $130 million project to keep visitors dry as they enter/exit the terminal buildings and enhance their overall experience.

Hartsfield-Jackson Atlanta International Airport (ATL) is in the midst of a $130 million project to keep visitors dry as they enter/exit the terminal buildings and enhance their overall experience.

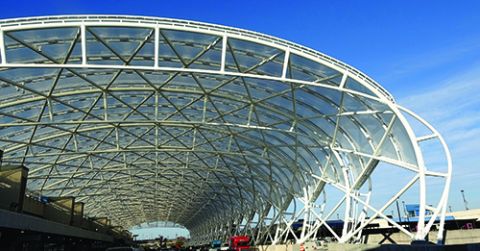

The North and South Domestic Terminals are mirror images of one another, each with eight lanes of traffic at their doorsteps and minimal protection from the elements. To solve the problem, ATL is erecting a canopy on each side that will span the roadways and sidewalks.

“When it now rains, there are sheets of water that come down on those unloading a car, and you really get wet,” says Jorge Cortes, ATL assistant director of Planning and Development. “By providing the canopy, we really provide an increased level of service for all our passengers.”

|

facts&figures Project: New Canopies & Exterior Facade Location: Hartsfield-Jackson Atlanta Int’l Airport Cost: $130 million Funding: Interim funding, commercial paper Special Feature: 3,700+ LED blubs that light canopies in multiple colors Construction Manager: New South-McCarthy-Synergy Design Team: HJ+P (joint venture of Stanley Love Stanley Architects, Chasm Architecture & HOK) Demolition: Atlas Demolition Steel Fabrication: Beck Steel Steel Erection: Derr & Isbell Deep Foundations: Berkel Civil Engineering/Sitework: Brent Scarbrough Electric Contractor: Cleveland Electric Concrete: Ely Construction Roofing Material: FabriTec Misc. Steel: IMMEC Drywall & Framing: Knight Construction |

This simple approach creates massive flexibility for the airport, notes Ripley Rasmus, the HOK principal architect in charge of the project. In the future, the system can adapt to potential changes in airline operations, the use of autonomous vehicles and refinements of curbside security.

In late November, the canopy project was about 50% completed. Construction crews were finishing up punch list items on the North side, and workers had begun erecting 19 steels trusses on the South side. The team expects to finish the steel work in April 2019.

Gary Summerlin, ATL’s design manager for the project, notes that some passengers driving under the new North Terminal canopy wonder why it is no longer raining. Even during a torrential downpour that dumped 6 inches of rain over just a few hours, passengers arriving and departing the North Terminal stayed dry. “It is like a large umbrella,” he remarks.

On the Sunday following Thanksgiving, two passengers endorsed the new feature on Twitter. “The canopy looks fantastic,” wrote one customer. Another re-Tweeted that observation and added, “I was thinking the same thing. So beautiful! Really impressive.”

The new canopy is also reducing maintenance, because crews no longer have to continually mop up water being tracked into the terminal during storms.

The steel erection took about six months; adding roofing materials, painting and installing lights took another two months, explains Dan Hobson, project executive for the construction joint venture of New South-McCarthy-Synergy. New South and Synergy are both based in Atlanta; McCarthy is based in St. Louis. New South has been involved in construction projects at ATL for 29 years.

Other elements of the $130 million modernization will include re-cladding the landside exterior with a new façade and building four sky bridges that “fly” through the space of the canopy and link the upper levels of the parking decks to the terminals. All the improvements are expected to be completed by the second quarter of 2021.

In addition to enhancing the passenger experience, project designers hope to create an iconic structure on the city’s horizon—and from the air. Replacing the 40-year-old façade of pre-cast concrete panels with metal and glass panels is one step in burnishing the exterior image of the building. The second is the installation of 3,708 LED lights to illuminate the canopy.

Bright Lights, Big Canopy

Each canopy is 900 feet long, with a space-age polymer roofing material: ETFE (ethylene tetrafluoroethylene, a fluorine-based plastic). Architects specified two layers to provide shade with a silver frit pattern on the outside layer, Hobson explains. Space between the two layers is inflated, creating a pillow-like look on the outside.

The ETFE allows overhead views of planes and the sky while providing shade, notes Rasmus. It also reduces solar gain by 50%. The equivalent of three football fields of the polymer material will be used to build the two large canopies.

ETFE, manufactured in Shanghai, was used in several of the venues for the Beijing Olympic games. The fabric-like material was also used in Atlanta on the new Falcons Stadium, but without the second layer to create the pillowy effect.

Lights are being installed every 12 feet on the cross beams between the trusses and are directed up to the translucent ceiling to create ambient lighting for the area below the canopy. However, the main purpose of the canopy lights is the effect they create to those approaching the airport.

The airport opted for LED lamps with programmable color options. According to Summerlin, the addition of color added a very nominal cost. As part of the lighting contract, ATL purchased adaptable software to create 12 different color themes with the lights.

“The addition of color will add more interest and help the airport emphasize the various holidays,” Cortes explains. “It will make the airport more appealing, and it will be a nice level of service for the passenger to come into.”

ATL plans to select color patterns based on the calendar and holiday themes. The effects will be controlled by photocells and pre-programmed dates. At the moment, the airport’s pre-programmed list does not include displays for any of the region’s professional or college sports teams.

White will be the everyday color for the canopies, and it makes the airport “glow” from a distance—by land or air.

While much of the work outside the North Terminal is complete, crews are still adjusting the lights and patterns. Summerlin notes that the white lights are energized as each bulb is installed. In November, three patterns had been tested and adjustments were still needed. The project team expects crews to complete the light installation on the South Terminal by the second quarter. The airport has not decided whether to turn on the patterns in the North Terminal before the South side is ready or wait until everything is complete.

While much of the work outside the North Terminal is complete, crews are still adjusting the lights and patterns. Summerlin notes that the white lights are energized as each bulb is installed. In November, three patterns had been tested and adjustments were still needed. The project team expects crews to complete the light installation on the South Terminal by the second quarter. The airport has not decided whether to turn on the patterns in the North Terminal before the South side is ready or wait until everything is complete.

The light bulbs are rated to last at least 10 years.

Per code, there are standard lights on light poles and directional signs to illuminate the area for passengers and drivers. There will also be fill lights from the trusses directed toward the renovated entries.

Erecting the Canopy

Before construction on the canopy could begin last spring, crews completed 16 months of site work. Portions of each parking garage were demolished to make way for the piers needed to support the 194-foot trusses. Although one side of each truss touches the terminal building, all the weight is placed on the new piers.

Each square pier is 21 feet tall and 11 feet wide. Micropiles, some up to 75 feet deep, are integral components of each pier system.

Each truss is 194 feet wide and 73 feet tall. The steel was rolled in Chicago and the trusses fabricated in Lubbock, TX. Each completed truss was then cut into five pieces to ease shipment and installation. On site, crews re-assemble the pieces to create three pieces: the column, mid-span and long-span. Crews are able to install just one section per night, and it takes three consecutive nights to erect one truss.

Once a truss is erected, crews then spend 10 days building the 48-foot-wide bay between each truss with 10 x-shaped cross beams. They also install additional steel to support the ETFE. The last step is installing the polymer roofing material. There are 18 bays in each canopy.

Because each truss spans eight lanes of traffic at the front door of the world’s busiest airport, crews effectively had just six hours of active construction each night, from 10 p.m. to 4 a.m.

“We could not shut down the movement of the passengers in and out of the building, and safety was our primary concern,” emphasizes Hobson. “Everyone from the general manager on down said the project was not to impact the passenger.” Work on the North Terminal canopy sometimes closed two to three lanes in each direction, but it never shut down all the roadways.

“This is a logistics project with a construction component” became a catchphrase among team members. “To the airport’s credit, they spent a lot of money to make sure that passengers could still get in and out of the airport,” Hobson remarks.

Steel erection is adjusted on a daily basis to accommodate ambient temperatures and the expansion/contraction of the steel components. Engineers calculate that the structure can expand or contract up to 3 inches.

Limited by airspace restrictions, crews use hydraulic cranes to lift the steel. Again, precise daily calculations are needed because the cranes are placed on a bridge rather than a solid surface. “Months of engineering went into making sure we would not exceed the weight that the bridge could support,” recalls Hobson. “The contractor had to order special cranes to make it work.”

Building the North Terminal canopy taught crews lessons they are applying to the South. “It is unusual in construction to build the exact project twice in a row,” Hobson comments. Crews familiar with each step are more effective and efficient in building the South canopy.

Hobson estimates that the second canopy will consequently take one month less than the first. Not only does he expect the total work time to drop to 10 months, he also predicts it will be completed more efficiently in a typical work week rather than the seven-day weeks it took to get the North side done.

Façade & Sky Bridges

Because the façade contractors could not work under the canopy as it was being built, construction on the North Terminal façade started after much of the canopy was completed. Hobson reports that about one-quarter of the North façade was completed by late November. On the other hand, crews got started on the South façade before crews moved in to start building the canopy.

The airport is also rebuilding each of its 12 entries—raising the ceiling to bring in more light and create grander entrances.

“We believe this project will be successful in recreating the brand, identity and experience of the Domestic Terminal, creating a new 50-year future for these facilities as ATL faces an era of unprecedented change in airline industry and the culture as a whole,” Rasmus comments.

Crews are scheduled to begin constructing the four sky bridges in the first quarter of 2019 and be completed by mid-2020. Work will begin on the North Terminal and then alternate between the two terminals, ending on the South Terminal.

2022 Charlotte Douglas International Airport Report of Achievement

Giving back to the community is central to what Charlotte Douglas International Airport and its operator, the City of Charlotte Aviation Department, is about, and last year was no different.

Giving back to the community is central to what Charlotte Douglas International Airport and its operator, the City of Charlotte Aviation Department, is about, and last year was no different.

Throughout 2022, while recovering from the COVID-19 pandemic, we continued our efforts to have a positive impact on the Charlotte community. Of particular note, we spent the year sharing stories of how Connections Don't Just Happen at the Terminal - from creating homeownership and employment opportunities to supporting economic growth through small-business development and offering outreach programs to help residents understand the Airport better.

This whitepaper highlights the construction projects, initiatives, programs and events that validate Charlotte Douglas as a premier airport.

Download the whitepaper: 2022 Charlotte Douglas International Airport Report of Achievement.